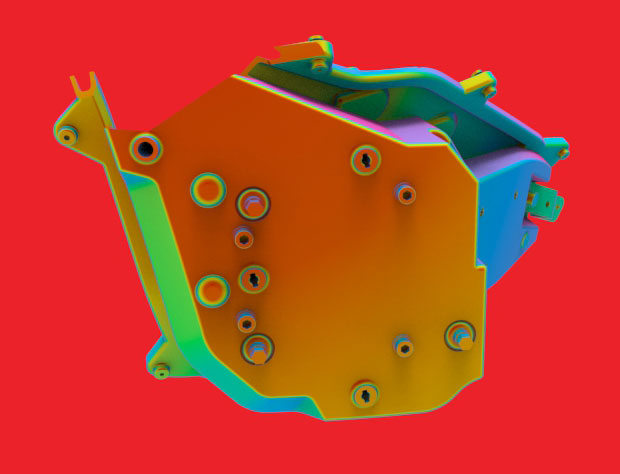

B.eng s.r.l. is a multi – disciplinal center in which some professional and qualified technicians and designers work, from initial phases in close contact with the Customer.

The engineering activities made are connected to traditional field of design (preliminary and definitive design process and productive feasibility) using technologies and qualitative standards required by the market.

The skills gained in design field, allow us to be operative in industrialization and optimization of the product because we can supply feasibility studies according to productive processes,